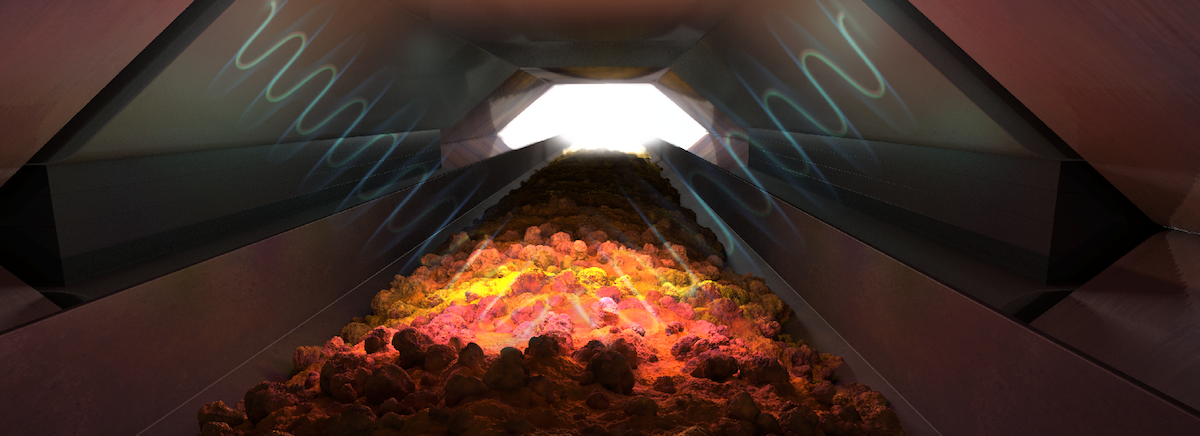

A new technology may accelerate ore sorting by illuminating batches of ore with short pulses of radio waves, assessing ore grade and enabling high tonnage sorting at rates of up to 5,000 tons per hour. The technology uses sensors to sees through large ore batches in real time as they pass through an open-ended chamber.

Called magnetic resonance technology (MRT), the method is being compared to an MRI in that it can detect the signatures of many minerals much in the way an MRI “sees into” human bodies.

Suited for a broad range of economically significant metals, the technology may be most beneficial for copper processing as it can detect copper minerals at extremely low grades. It is also particularly useful for gold in that it can detect arsenic-bearing minerals that are often positively correlated with gold in sulphide ore deposits.

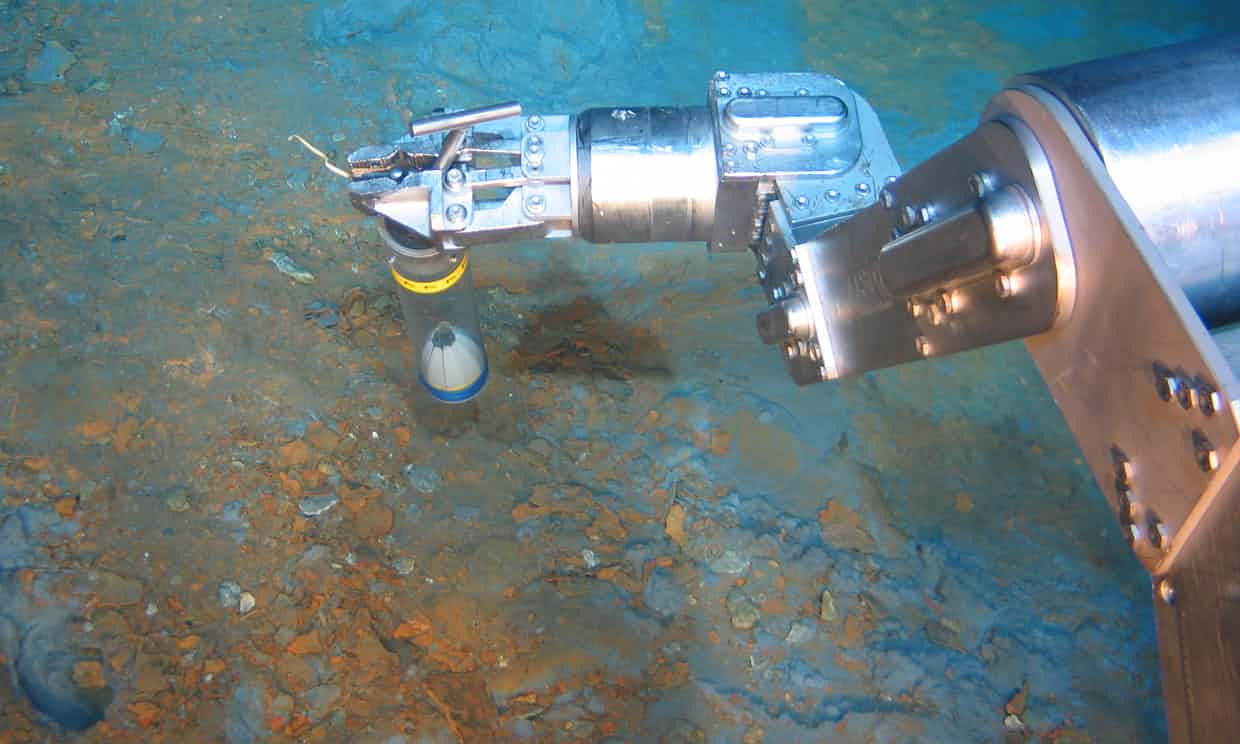

The sensing technology was developed by NextOre, a company formed by CSIRO, Advisian and RFC Ambrian. Initial testing was conducted at the Newcrest Ridgeway mine near Orange in New South Wales, Australia. RFC Ambrian associate director Chris Beal is serving as acting CEO of NextOre and indicates that industry reaction to this new ore-sorting technique has been very positive.

NextOre’s bulk ore sorting solution is currently available for deployment.