MINING MAGAZINE | 15 December 2017

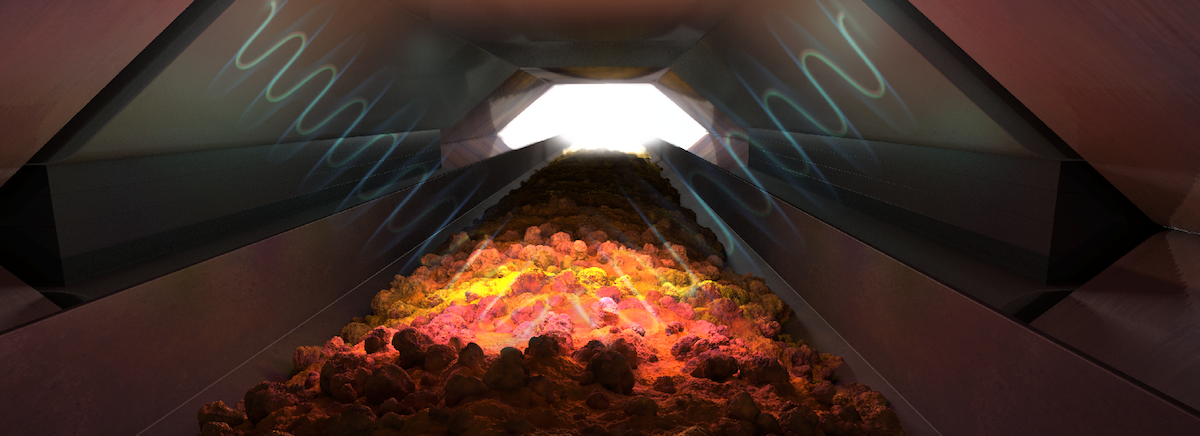

“The technology’s advanced sensor system takes advantage of magnetic resonance technology. It illuminates batches of ore with short pulses of radio waves, assessing ore grade and enabling high tonnage sorting at extremely high speeds.

NextOre’s ore sorter is able to detect the magnetic resonance signatures of many minerals, including the most common economically significant iron- and copper-bearing minerals. It also has the ability to detect arsenic-bearing minerals that are often positively correlated with gold in sulphide ore deposits. It can see through large ore batches in real time, as they pass by the sensors contained in an open-ended chamber.”