The demand for cobalt to power a carbon-free future has been a core narrative as the deep-sea mining industry has grown over the last decade. Cobalt is a relatively rare ore whose terrestrial extraction has been rife with humans rights issues and environmental harm. Accessing a reliable supply of cobalt that could not only satisfy the demand for the element but also stabilize the dramatically fluctuating commodities market which drives fly-by-night artisanal cobalt mining would go a long way towards alleviating many of the problems associated with cobalt extraction.

But, while some stakeholders have focused on cleaner, safer, ways of extracting cobalt to meet the demands of next-generation energy technologies, others have focused on reducing or eliminating the need for cobalt in batteries. Cobalt-free batteries have been the holy grail for battery manufacturers supplying power cells to electric vehicle companies, including Tesla, but, until recently, an efficient, durable, cobalt-free battery technology has been just out of reach.

Cobalt is used to prevent corrosion and stabilize the cathode in a Lithium-Ion battery. Without cobalt, these batteries have a short life and low energy density, making them inappropriate for use in things like electric vehicles or mobile devices, which need a consistent lifespan and stable voltage. Recently, researchers at the University of Texas unveiled a cobalt-free battery that uses a nickel manganese aluminum oxide cathode which meets the performance requirements for a commercial battery.

Unlike other new battery technologies, like solid state batteries that provide fast, efficient charging-cycles and a lower risk of catastrophic failure, cobalt-free lithium ion batteries do not require major retooling of existing battery production chains. Toyota, famously, has yet to enter the electric vehicle market as it focuses on the development of its own solid state battery and production supply chain. These new cobalt-free cathodes can be incorporated into existing manufacturing processes, allowing them to be brought from concept to commercialization without significant capital investment into new facilities. The research team has already begun working towards commercialization, creating the cathode company TexPower and working to integrate the new cathode into existing production lines.

Cobalt isn’t the only essential element found in polymetallic nodules on the seafloor. These new batteries still require nickel for the cathode. Unlike cobalt, which is mined in abundance at only a few places in the world, nickel deposits large enough for commercial exploitation can be found on every continent, with major mines in Canada, Indonesia, Brazil, Russia, South Africa, Australia, Colombia, Madagascar, and Finland, among others. Cobalt is often found as a secondary ore in nickel laterites.

While the primary justification for dramatically expanding cobalt production lies in the electrification of the world’s vehicle fleet, nickel has a much broader and more stable use case. A little more than 3% of global nickel production goes into batteries, while nearly 75% of annual nickel production goes towards the manufacture of stainless steel. Manganese and copper are also found in commercially exploitable quantities in polymetallic nodules.

Gerard Barron, CEO of DeepGreen, is unconcerned about potential shifts in cobalt demand. “The drive for cheaper cathodes will inevitably reduce the dependency on cobalt, and yes we will see [electric vehicle] batteries containing zero cobalt,” says Barron, “but if there was a more abundant supply of cobalt, and if that could mean cobalt was priced closer to nickel, I’m pretty sure that every EV battery would have some cobalt in it as it provides some unique benefits. From our perspective, we are not worried about cobalt. It’s a small market today that even with zero or near zero cobalt in EV batteries will still grow significantly due to other use cases.”

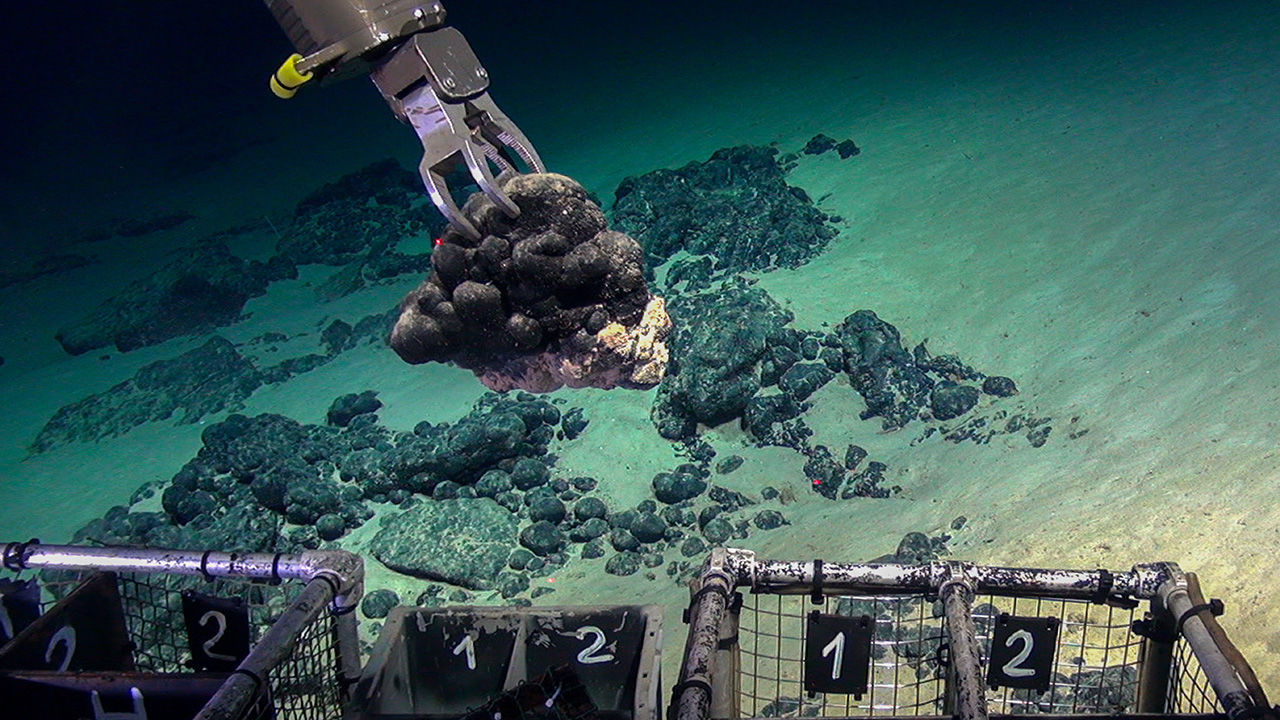

Featured Image: Cobalt-rich Crusts collected from the Tropic Seamount. Photo courtesy NERC.