Although the political negotiations surrounding the establishment of a Mining Code are frequently the driving factor in the development and advancement of the deep-sea mining industry, the technology necessary to actually access the seafloor and recover ore from the deep ocean presents just as many challenges. The rules of the International Seabed Authority even provide for a contractor who currently has the technical capacity to initiate a deep-sea mining program to accelerate the code-writing process. With negotiations underway and an optimistic time frame of 2021 for the final Mining Code, just how close are contractors to being able to exploit seabed resources in areas beyond national jurisdiction?

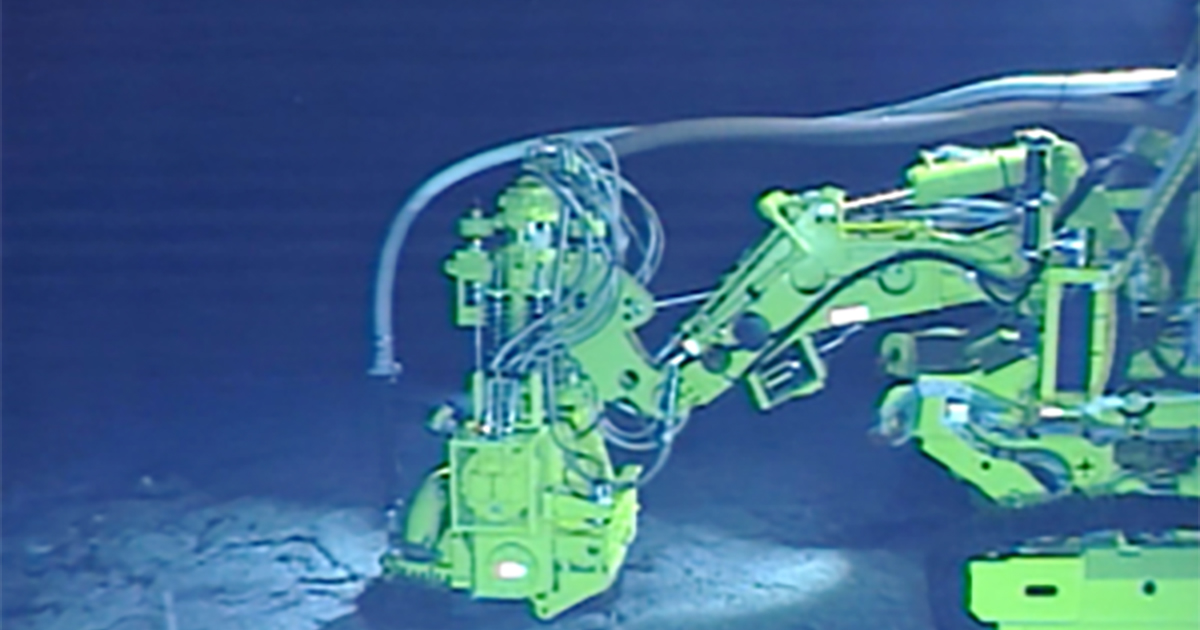

Of the state-sponsored contractors, Japan seems best positioned to begin commercial mining of the deep seafloor. Last month, the Japan Oil, Gas, and Metals National Corporation revealed that they had completed the first successful excavation of a cobalt-rich ferromanganese crust within Japan’s exclusive economic zone. An experimental excavation vehicle recovered 650 kilograms of ore from the surface of the Takuya 5 seamount.

Though this is a first of kind test, the collection vehicle itself is substantively similar to the vehicle used by JOGMEC in 2017 to recover ore from seafloor massive sulphides from the area around the Ryuku Islands. The traction and collection system appear identical, with only apparent changes to the cutting head and the addition of a dredging hose. A cyclone tank has been connected to the rear of the vehicle where it previously held what appeared to be a collection hopper.

As such, this project represents less a technological advancement in the extraction of ore from the deep ocean than a priority shift from seafloor massive sulphides to cobalt-rich crusts. JOGMEC noted that the Takuya 5 seamount could meet Japan’s demand for cobalt for the next 88 years and its demand for nickel for the next 12 years. There is still a long road ahead as JOGMEC researchers develop mineral processing protocols and scale up the refining and smelting process to meet commercial production demands.

“The test was confined within the very limited area while the total area of the seamount flat top is 2,200 [square kilometres].” says Saeko Nojiri of JOGMEC. “We conducted environmental baseline surveys around the test area in reference to the ISA’s environmental guidelines and extracted possible environmental impacts considering a scale of the test. We have surveyed throughout the test for environmental impacts and the obtained data will be analyzed. We are planning to publish the results of this environmental study eventually.”

JOGMEG currently has a single exploration contract for cobalt-rich crusts to the east of the Mariana Trench in the area beyond national jurisdiction. Their long-term plan is to identify prospective mining areas within that lease by 2023.

“Based on the 2019 Japanese Government Ocean Energy & Mineral Resource Development Plan,” continues Nojiri, “we pursue possibility of the development of cobalt-rich crust on both seamounts in Japan’s EEZ and the ISA contracted area by Japanese private sectors by 2028. Toward that end we continue mineral processing and smelting & refining tests using the collected crust as well as various approaches including resource estimation, design of a new excavating machine specialized for the crusts and environmental study on the seamounts.”

DeepGreen announced earlier this year that it had formed a $150 million partnership with the offshore construction and logistics company Allseas. “Together with Allseas,” says DeepGreen CEO Gerard Barron, “we’ll engineer a deep ocean nodule harvesting system that will have minimal impact to the deep sea environment, enabling us to bring what we call clean metals to market in order to power some of the one billion electric vehicles that are forecast to be produced over the coming three decades.” Though there have been no major updates on the development of the nodule harvester, Allseas has already acquired the 228 meter long deepwater drillship Vitoria 10000 and begun the conversion to a mining collection vessel. According to AIS logs, the vessel is currently moored in Kristiansand, Norway.

GSR continues to make strides with the Patania 2 system. Following setbacks during their previous campaign, where the tether system failed during deployment, GSR has now successfully tested an upgraded system on a recent Atlantic deployment and plans are underway to once again return to the Clarion-Clipperton zone to test the Patania 2 nodule harvester platform in the deep Pacific Ocean in 2021. The Patania platform, to date, is the only modern nodule collection system to have undergone testing within the CCZ.

Royal IHC also built and tested the Apollo II nodule collector and conducted a plume and disturbance study in conjunction with the Blue Nodules project. This small-scale crawler system is primarily designed to test operational systems and environmental impacts before scaling up to larger systems.

This summer, the Government of India’s Ministry of Earth Sciences submitted an environmental impact statement for the testing of a prototype nodule mining crawler in the Central Indian Ocean Basin. Those tests, which will be conducted in 2021, will look at both the effectiveness of the collection system and the potential environmental impacts of the process. India also has major plans in the works for other submersible systems which will be used to support a host of Blue Economy goals over the next decade, including enhancing offshore mining capabilities.

UK Seabed Resources, a wholly owned subsidiary of Lockheed Martin, pioneered polymetallic nodule collection in the late 1970s and 1980s, and developed many of the early collection vehicles, however there is no publicly-accessible information regarding any current mining tool development or vessel acquisition. Lockheed Martin has filed several patents for nodule collection-related systems over the past decade, suggesting that technical development is progressing.

Krypton Ocean made a splash in 2018 with a novel untethered nodule collector design, however, the company has not provided updates since 2018 and does not appear to be currently active.

Finally, though Nautilus Minerals is no longer in operation, the company did manage to construct and partially test three seafloor production tools designed for the recovery of seafloor massive sulphide deposits off the coast of Papua New Guinea. Publicly available satellite tracks indicate that the three mining tools remain at the Papua New Guinea Dockyard in Port Moresby, where they have been housed since at least mid-2017. In addition to the three seafloor production tools, Nautilus also began construction on a support vessel, before defaulting on financing and eventually declaring bankruptcy. That ship was acquired by another company and renamed the Amaya Explorer, however, no ship matching that name or bearing that vessel’s IMO number has an active AIS signal.

Notably, though technological development has been proceeding apace, with significant progress towards a full-scale commercial mining system, one major hurdle still has not been overcome. No contractor or member state has yet demonstrated a functional riser-and-lift system which will carry unprocessed ore to the surface support vessel and return tailings or a dewatering plume to the seafloor or mid-water. This technical hurdle likely represents the last major hardware gap that must be bridged before commercial mining can commence.

Featured Image: JOGMEC crust excavation tool. Photo courtesy JOGMEC.